Urethane Resin Casting

To make reproduction parts of anything Resin Casting is a common method. This essentially involves building a mold out of Silicone, and pouring in a Resin to create a duplicate. The material properties of the resulting part can be selected and Controlled depending on the Resin that is selected.

The mold should include provisions to identify the part that is being cast, retention and alignment features, and be as self explanatory as possible.

Planning

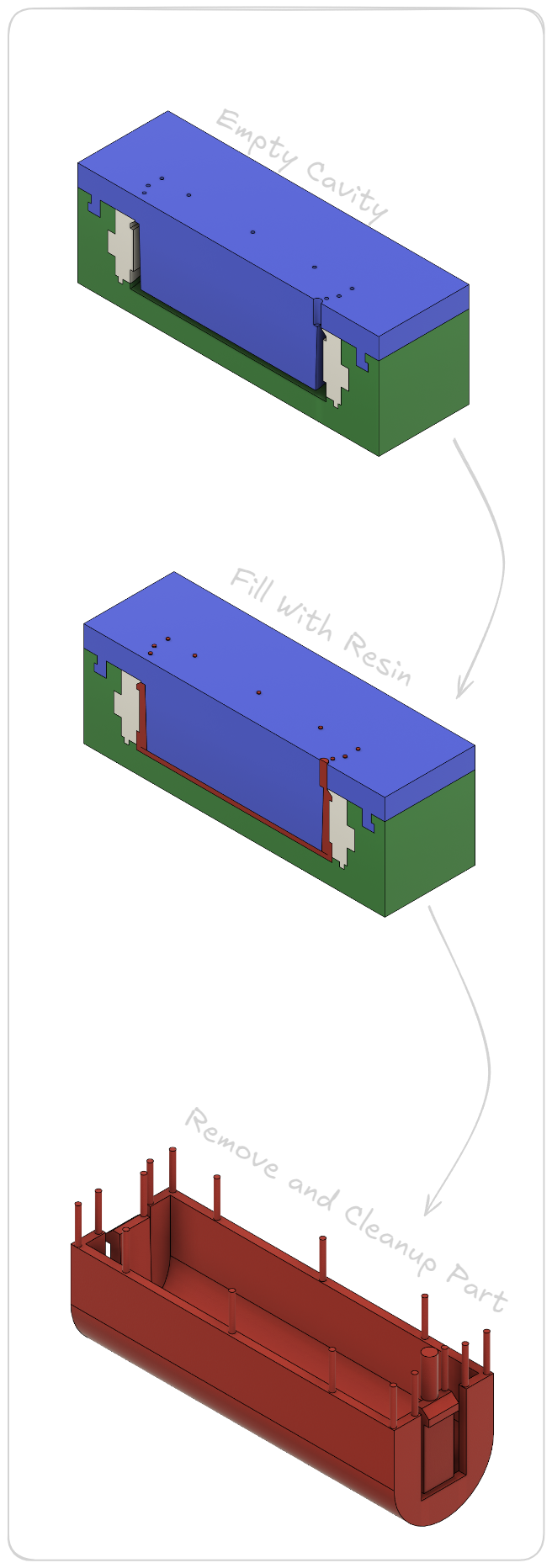

Casting is pretty similar to injection mold part design, in that you need to create an empty void that gets filled with plastic, and need to be able to get the part(s) out of the mold once you're done. This necessitates a little bit of planning about how a mold will go together/come apart.

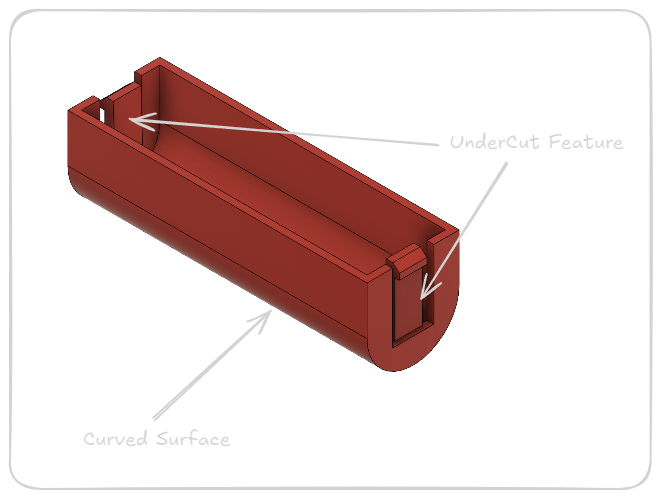

Thinking about parting lines, undercut sections, and areas of high curvature are all necessary

Silicone is SIGNIFICANTLY more forgiving than steel though so a quick plan for order of operations is typically enough.

Typically all molds require the following:

- Mold Core

- Mold Cavity

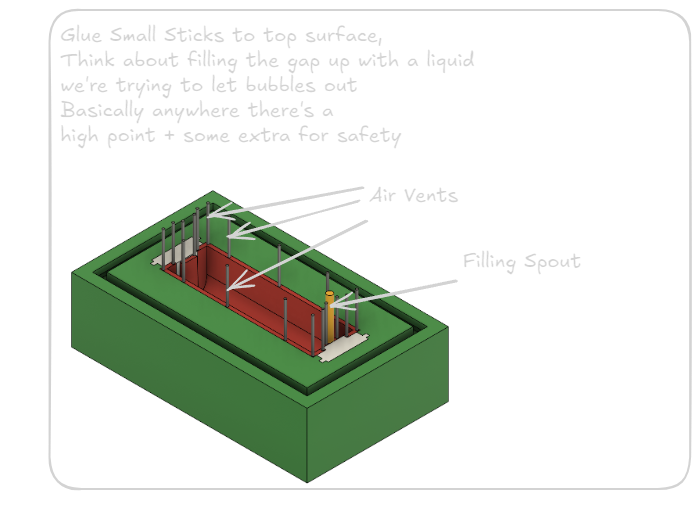

- Filling Spout

- Air Ventilation

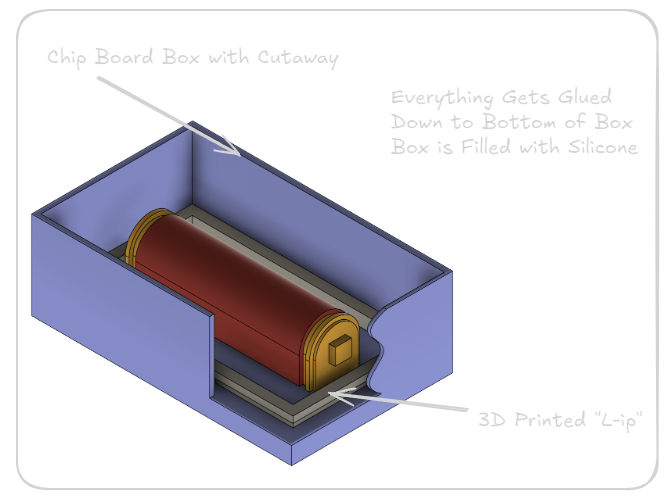

Mold Box Building & 3D printing

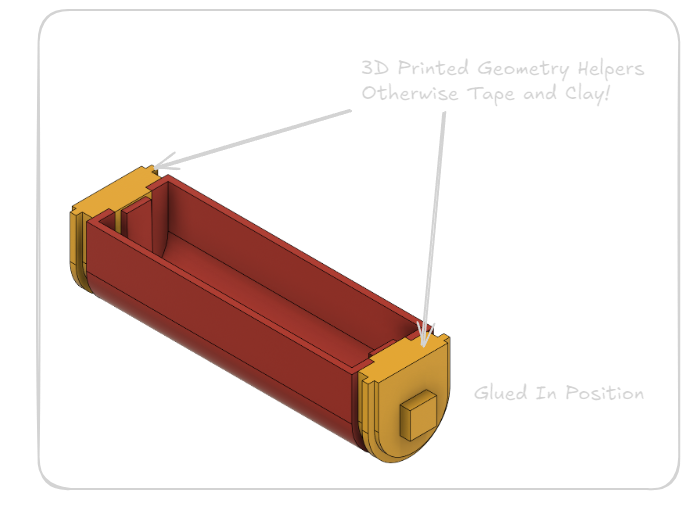

For parts where CAD is available 3D printing can be a major time saver. Printing bucks and spacers to define the shape of the mold components can save ton of resin and increase quality of the outcome. Otherwise many of these features can be created with hot glue and chip board.

Features to include with 3D printing when available

- Alignment/Keying Features

- Identification Plaques

- Retention grooves

- Inserts

- Secondary Actions

Things that are easier to add by hand

- Filling Spout

- Air Ventilation

- Mold Box for Core and Cavity

Mold Side A (Could be Core Or Cavity Depending on Geometry)

It's hard to give generic enough advice to be useful for all parts. Typically you want to find the flattest face and glue that down to the board, OR build up a little bit of a support piece to "suspend" the part. PVA (normal Elmers) glue is great for this. If there are Undercuts on the part, blocking out those sections either with clay as needed.

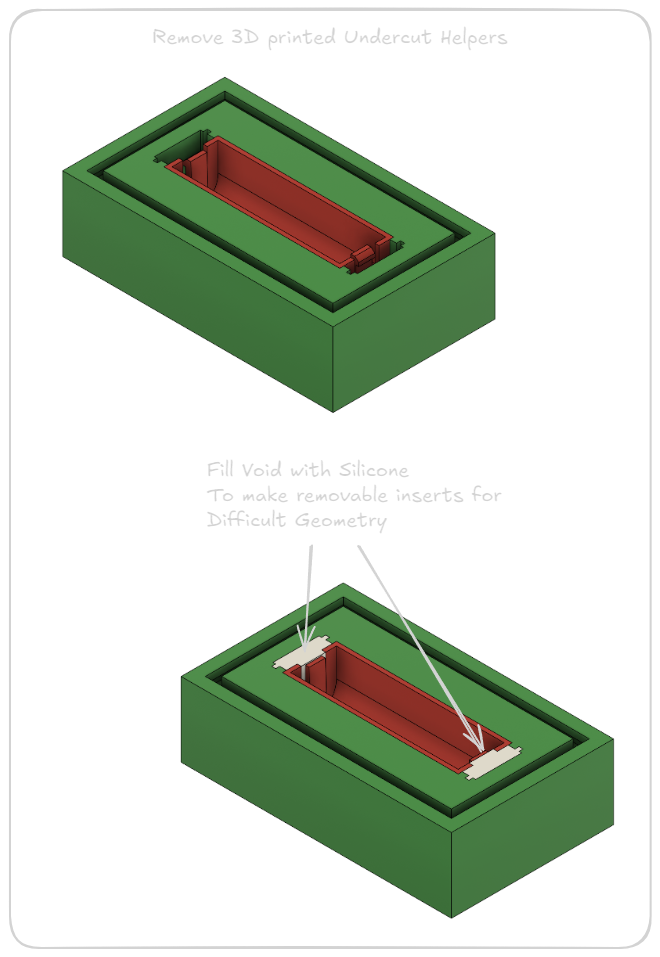

Inserts

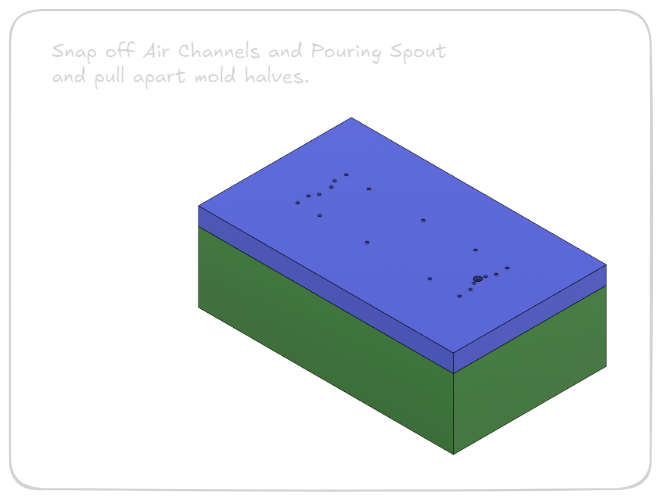

Air Vents & Filling Spout

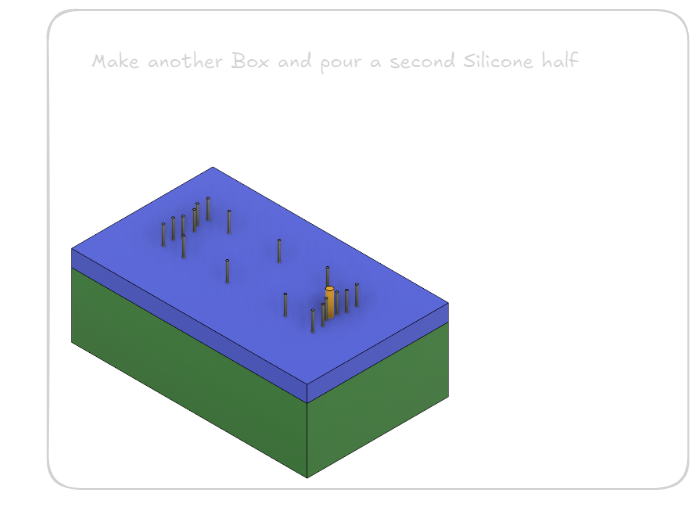

Mold Side B

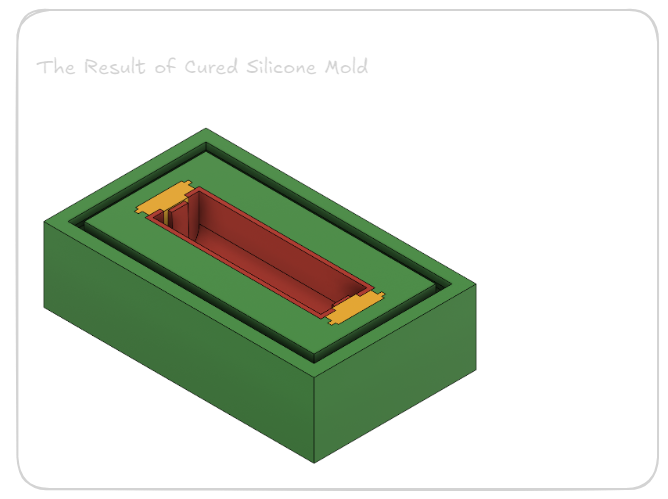

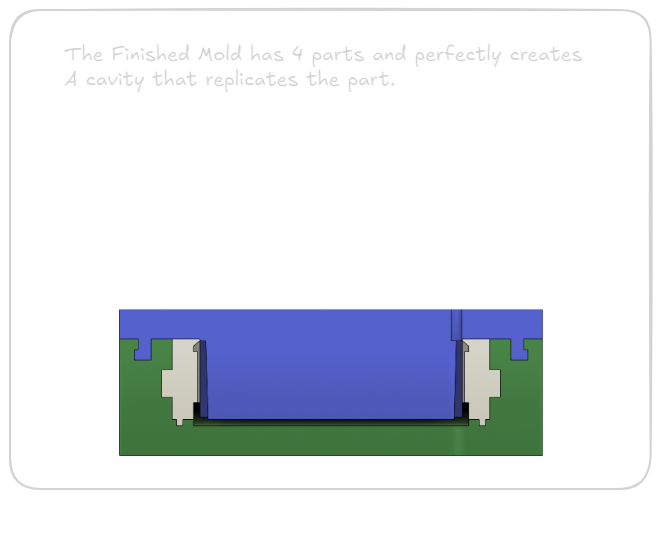

Finished Mold

Casting Process